※朝顔:道路などに面した工事現場で使用され、仮設足場からの落下物による危害から通行人等を守る防護棚。

職人不足の課題解決に挑む「SpeeK」

そもそもなぜ、くさび式足場のレンタル・販売をするASNOVAがオリジナル製品、くさび緊結式次世代シート朝顔SpeeKを開発することになったのか。背景には、建設現場での深刻な職人不足があります。コロナ禍の影響で、就職活動は売り手市場から買い手市場へ移行したと言われていますが、建設業界は変わらず職人不足に悩まされているのが現状です。

厚生労働省の「一般職業紹介状況」を見ると、2021年12月のとび職を含む建設躯体工事の有効求人倍率は9.35倍であり、他の職業に比べて深刻な人手不足となっていることがわかります。

また、2021年の国土交通省による「建設業の働き方改革の現状と課題」によれば、建設業就業者のうち29歳以下が約12%であるのに対し、55歳以上が約36%を占め、業界の10年後、20年後を見据えた際、職人不足の影響はますます大きくなると予想されます。

こうした課題に立ち向かうべく、ASNOVAではかねてより業界全体の働きやすさや施工の効率性アップに取り組んできました。その1つとして、2021年本格的にレンタル・販売を開始したのがSpeeKです。

SpeeKの1シート分の施工に必要な部品

SpeeKの1シート分の施工に必要な部品

従来の朝顔は、面板がスチールやFRPの商品が中心のため、重量があり、安全面や作業面で施工人数が多く必要でした。また、ボルトやナットなど細かい部品を紛失するリスクもあり、管理の工数もかかっていました。同時に、部品数が多いほど設置や解体、台風養生に時間がかかることも、人材不足の現場の負担になっていました。

そうした課題を解決するため、SpeeKは従来品より約38%軽量化(ASNOVA調べ)し、部品数は半数以下の9点に。また、くさび緊結式の施工方法により作業効率を向上することで、熟練の技術を持った職人ではなくても、ハンマー1本で効率的に作業を進められる朝顔を開発しました。

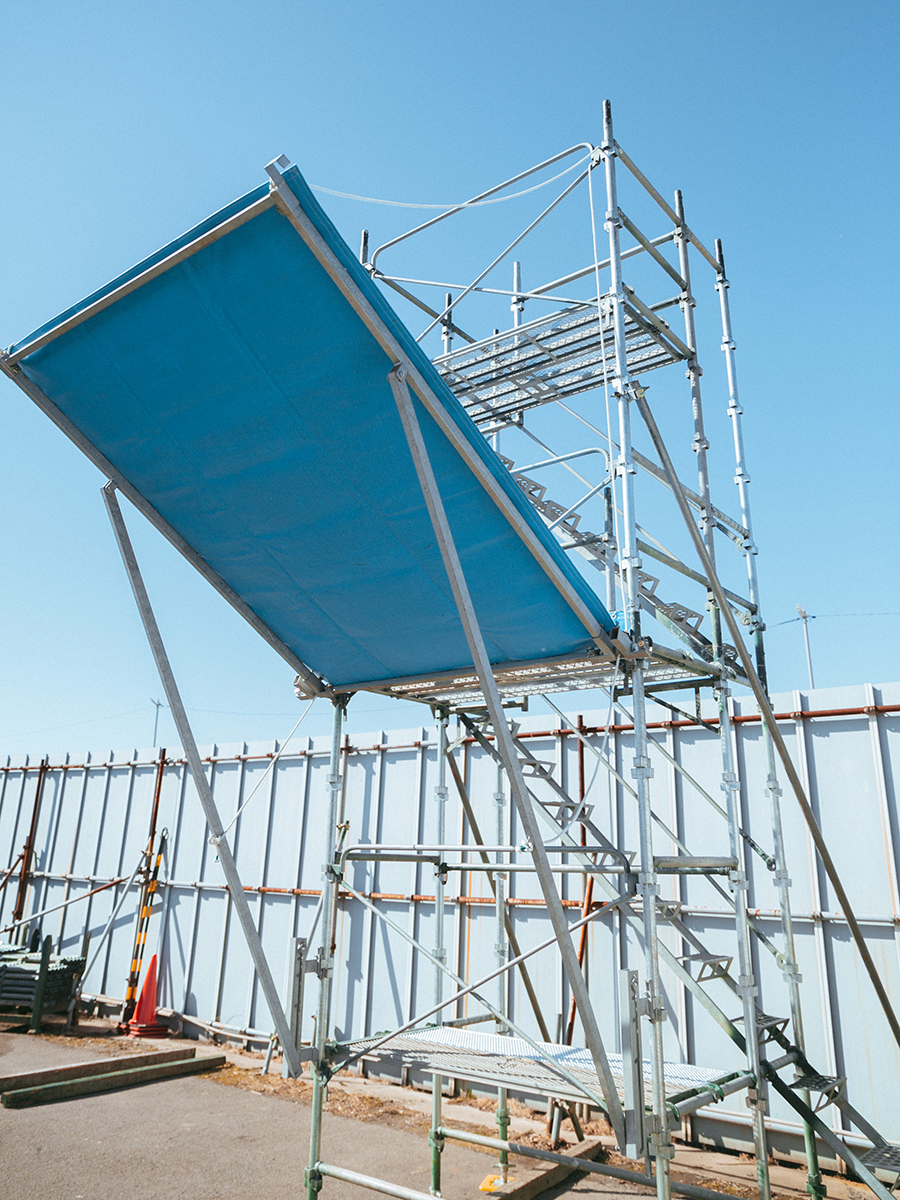

ここからは、現場経験のないASNOVAの新人社員が実際にSpeeKを施工する様子をお伝えします。

新人社員が施工を体験

今回訪れたのは、足場施工業者への出荷、搬入、検品を行う「愛知一宮センター」。ここで、機材管理部 中部エリア長の内田寛次さんの指導の下、入社1年目で営業部 名古屋営業所の笠原翔さんと事業企画室の阿南元春さんがSpeeKを施工しました。

左から、笠原 翔さん(営業部 名古屋営業所)、内田 寛次さん(機材管理部 中部エリア長)、阿南 元春さん(事業企画室)

左から、笠原 翔さん(営業部 名古屋営業所)、内田 寛次さん(機材管理部 中部エリア長)、阿南 元春さん(事業企画室)

内田さんの指示に従い、早速足場を組み上げていきます。安全性確保のため、基本的に2人1組で作業に当たります。

まずはSpeeKの特徴である、下部金具(くさび緊結式のASNOVAオリジナル金具)を取り付けるところから。

内田:従来の朝顔はメジャーで長さを測らなければなりませんでしたが、くさび緊結式になったことで、一定間隔に採寸する手間が省けました。これだけでも大幅に作業効率がアップしました。

左右のくさび緊結式の金具をつけた後は、下部フレームと上部金具を設置していきます。

続いて、本体フレームと斜材を取り付けていきます。二人でしっかりと支えながら、下部金具と上部金具に固定します。

最後に上部フレームを取り付けます。あっという間にフレームの設置は完了です。

次に角度調整をするためのロープを上部フレームと本体フレームに括り付けてから、朝顔用シートを張っていきます。

内田:台風の際は、シートをめくってロープで柱に括り付けておくことができます。出し入れが簡単なので、台風養生も迅速に対応できるようになりました。

これでセットは完了。最後に、シート部分を開いて完成です。

ここまで約15分。現場経験のないスタッフでもスムーズに組み立てることができました。足場施工の職人さんであれば、当然もっと早くできます。

内田:アルミ式やスチール式の朝顔を施工したこともありますが、SpeeKができてから大幅に時間を短縮することができています。作業に慣れれば、5分もあれば組み立てられるようになりますよ。

難しい職人仕事を、誰でもできる仕事に

初めてSpeeKの組み立てを体験した笠原さんと阿南さん。笠原さんは営業、阿南さんは事業企画の業務に普段は従事しています。そして二人を指導した内田さんは、元々は営業職。普段の業務も経歴も異なる3人それぞれの視点から、SpeeKを施工してみた感想やSpeeKにかける思いを伺いました。

実際にSpeeKを体験してみていかがでしたか?

笠原:やり方も使い方も何もわからないところからでしたが、スムーズに施工することができました。段取りを一度覚えてさえしまえば、誰でも簡単にできるものだと思います。

阿南:足場に登ったのも今日が初めてでした。上に登ると、下から見るよりも思ったより高さを感じましたが、やることが明確で、安心して作業することができました。

体験前後でSpeeKの印象が変わったところはありますか?

笠原:前情報の通り、本当に簡単にできました。特にくさび緊結式の金具によって、決められた位置に打ちつければ組み立てが完了するのは便利ですね。また、部品点数が9点と少ないため、作業場での管理も楽でした。

普段の営業の仕事をされていて、お客さんの反応はいかがですか?

笠原:興味は持っていただくものの、新製品には慎重な姿勢を見せる方が多いです。しかし、一度でも使われた方は、「作業が楽だし、人件費や作業時間を踏まえるとトータルコストは、従来のものよりSpeeKの方が安い」とおっしゃる方が多いですね。

今後の展開について教えてください。

阿南:建設業界には職人しかできない仕事も多くあります。人材不足の中、SpeeKは時間効率化に繋がる製品だと思います。今後も弊社だから生み出せる製品を開発し、業界の課題解決に繋げていきたいです。

内田:年々、簡単に施工できる製品が出てきていますが、まだまだ現場に行くと素人は何もできないレベルのものです。それくらい、職人さんがやっている仕事は難しいことです。しかし人材不足の中、職人さんに頼ってばかりではなく、誰にでもできる仕事にしていかなければならないと感じています。その第一歩が、SpeeKです。SpeeKのような製品を今後も生み出し、業界の課題解決に貢献していきたいですね。